paper

smelting technology of medium and low carbon ferromanganese

updated: 2022-04-26 attention:

the raw materials for the production of medium and low carbon ferromanganese include manganese silicon alloy, manganese ore, lime and fluorite. the raw materials used in oxygen blowing decarbonization method are mainly high carbon ferromanganese. in order to produce medium and low carbon ferromanganese that meets the standard requirements and obtain good technical and economic indicators, all raw materials must meet certain quality requirements. the main production methods of medium and low carbon ferromanganese include electro silicothermic method, shaking furnace production method, oxygen blowing production method, bolun method and udacon converter method.

1、 raw material requirements

1. silicon manganese alloy

the production of medium and low carbon ferromanganese mainly by electro silicothermic method and shaking furnace method needs to use manganese silicon alloy. because the content of silicon and carbon in manganese silicon alloy is inversely proportional to each other, the main source of carbon in medium and low carbon ferromanganese products is manganese silicon alloy used as raw material. in order to distinguish from the manganese silicon alloy provided to steel mills, each medium and low carbon ferromanganese production plant, in combination with the actual situation, organizes a stable and reliable supply of intermediate product manganese silicon alloy that meets the requirements of enterprise standards. in the process of production organization balance, it is best to control the manganese content of manganese silicon alloy at the upper limit level, because it is very difficult to greatly improve the manganese content of products by relying solely on the smelting process of medium carbon ferromanganese. for example, organize the production of femn80c1 5 grade medium carbon ferromanganese, the manganese content of the corresponding intermediate product manganese silicon alloy should be controlled at about 69%. the intermediate product manganese silicon alloy is provided to the medium and low carbon ferromanganese smelting process in liquid or solid form. the slag on the surface of liquid manganese silicon alloy shall be cleaned before hot mixing, and carbonaceous inclusions are not allowed the solid manganese silicon alloy should adopt the bottom casting product that is sedated for a period of time after being discharged from the furnace, and the particle size after crushing should not be greater than 50mm.

2. manganese ore

the requirements of medium and low carbon ferromanganese production for manganese ore are that the ratio of manganese to iron should be high, the ratio of phosphorus to manganese should be low, and the content of silicon dioxide should be low. two or more kinds of manganese ores are usually matched with each other to meet the comprehensive quality requirements of low-carbon ferromanganese of various grades for the ore entering the furnace. in the simple production process of medium and low carbon ferromanganese, the alloying rate of manganese in the ore is closely related to the implemented process system. with different process systems, the alloying rate of manganese in the ore also shows corresponding differences. the particle size of manganese ore into the furnace shall not be greater than 50mm, and the moisture content shall be less than 6%. in particular, manganese ore directly used in shaking furnace or converter must be roasted and dried before use, so as to avoid personal and equipment accidents in production. the mn fe ratio of manganese ore can be reduced by 1.5-2.0 by adopting the shaking furnace pre refining process.

3. lime

the lime for smelting medium and low carbon ferromanganese requires that the content of calcium oxide should be greater than 85%, and the particle size into the furnace should be 10-60mm, and the content of particle size should be more than 80%; the lime shall not be mixed with harmful impurities such as coal blocks, and the sum of green burning and over burning rate shall not be greater than 10%. where conditions permit, calcined dolomite can be used to replace part of lime, so as to improve the content of magnesium oxide in slag, which is conducive to improving the recovery rate of manganese and reducing the power consumption of products.

2、 electrosilicothermic production process and smelting operation

in order to improve the recovery rate of manganese, reduce smelting power consumption and improve economic benefits, domestic and foreign manufacturers have made unremitting efforts to boldly reform the original production process and achieved remarkable results, so that the technology of producing low-carbon manganese by electrosilicothermal method has reached a new level.

1. production of medium and low carbon ferromanganese by hot charging

this method was first adopted by niigata factory in japan, so it is also called niigata method., using the combination of submerged arc furnace and rotary refining furnace, the manganese silicon alloy produced by submerged arc furnace is hot mixed into the refining furnace to produce medium and low carbon ferromanganese. the medium manganese slag produced by submerged arc furnace is condensed and broken for manganese silicon alloy production. in actual operation, in order to protect the furnace lining and improve the utilization efficiency of electric energy, after the last furnace tapping is completed and the furnace hole is blocked, rotate the furnace body and quickly tamp the material around the furnace wall. then the speed is regulated, the feeder is turned to the furnace, and the burden is mainly lime. the base note is manganese ore. after the distribution, the material surface between the electrode and the furnace wall shall be a concave ring. while waiting for the liquid manganese silicon alloy to enter, the waste heat of the furnace body is used to preheat the furnace charge. after the liquid manganese silicon alloy is weighed, rotate the furnace body and pour the alloy liquid into it to make the alloy liquid convection evenly in the concave ring. then put down the electrode for power transmission and add the adjusting material. after the furnace material near the pole center circle is basically melted, rotate the furnace body again to accelerate the melting of the surrounding furnace material and accelerate the desilication reaction under the action of external mechanical stirring; after the surrounding furnace charge is basically melted, take samples to judge the silicon content of the alloy, and discharge the furnace after it is determined to be qualified. the slag alkalinity of medium manganese slag should be controlled at 1.1-1.3. at this time, the manganese content in the slag is about 22%.

compared with the cold charging method, the hot charging method has the following advantages: shorter smelting time and lower smelting power consumption. as the manganese silicon alloy is fed in liquid form, the time required for remelting the manganese silicon alloy is saved, and the electric energy required for heating the charge is reduced by preheating the charge. compared with the cold charge method, the hot charge method shortens the smelting power consumption by more than 15 minutes and reduces the smelting power consumption by about 50%. the daily output of hearth is increased. after adopting the hot charging method, the smelting cycle of each furnace is shortened, the number of furnace sunrise is increased, and the daily output can be increased by about 25% compared with the cold charging method. the hot charging of liquid manganese silicon alloy into the furnace simplifies the slag pushing, casting, finishing and processing of manganese silicon alloy after being discharged, improves the metal yield of manganese silicon alloy, reduces the labor intensity of workers and reduces the production cost. the advantages of hot charging method are obvious, but the disadvantage is that it can not solve the problem of high residual manganese in slag. even if high alkalinity slag operation is adopted, the manganese in slag is about 12-18. medium manganese slag with slightly lower slag basicity and no pulverization as a by-product is usually used in the production of manganese silicon alloy.

2. production of medium and low carbon ferromanganese by cold charging

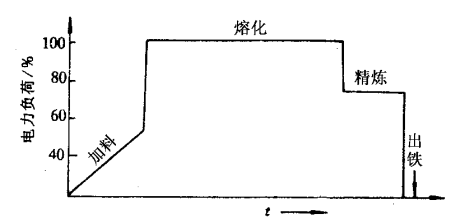

cold charging method is a traditional method to produce medium and low carbon ferromanganese. most of the refining furnaces used in it are transformed from steelmaking electric arc furnace, that is, tilting graphite electrode refining furnace. the smelting process of medium and low carbon ferromanganese is divided into five links: furnace repair, arc striking, feeding, refining and out of furnace casting. after the iron of the previous furnace is discharged, the iron outlet shall be blocked. after the furnace is repaired, the arc shall be started with the help of the residual slag and iron liquid in the furnace, and then the mixture shall be added into the furnace to melt the furnace charge with full load. after 60-70% of the charge is melted, use tools to push the charge melted at the end of the furnace wall around the furnace core and electrode. after the charge is basically melted, the smelting enters the refining period. in order to accelerate desilication and shorten refining time, the molten pool needs to be stirred, and samples from the molten pool regularly to judge the silicon content of the alloy. after the alloy is qualified, it can be discharged from the furnace. the judgment of silicon content is usually based on experience and visual observation. when the silicon content is greater than 2%, the condensation speed of the sample is slow, the surface is smooth, the black spots on the skin are easy to fall off, the section is bright, the crystalline particles are coarse and glassy. when the silicon content is less than 2%, the sample condenses quickly, the surface wrinkles are obvious, the black patches do not fall off, the section is dark and gray white, and the crystalline particles are fine. the lower the silicon content, the more obvious these characteristics are. if you still have little confidence in the judgment of the sample, you should immediately send it to the laboratory in front of the furnace for rapid analysis. the ladle with large volume is used for discharging and connecting iron, and the slag and molten iron are loaded at one time. when the molten iron is poured into the ladle, the good dynamic conditions formed by mixing with the slag are further desilicated to reduce the silicon content of the product. the slag iron in the furnace shall not be discharged completely, but a part shall be left to facilitate the electric arc striking of the next furnace and protect the refractory brick lining at the bottom of the furnace. the temperature of molten iron just released from the furnace is relatively high, so it is easy to burn the ingot mold immediately. it needs to be cooled down for a period of time before casting; since there are many solid-state phase transitions and corresponding true density changes in the cooling process of medium and low carbon ferromanganese, in order to reduce the serious fragmentation of products caused by excessive internal thermal stress during rapid cooling, slag capping casting is needed; the depth of the ingot mold for casting should not exceed 300 mm, otherwise the alloy in the center will be enriched with impurities due to slow cooling and solidification segregation, and the product will be rejected in serious cases. the basicity of slag for smelting is mostly related to the grade of manganese ore. in the early stage of smelting of each furnace, chemical material is the main task. in order to reduce the carburization of electrode to alloy and melt the furnace material as soon as possible in a large range, a higher secondary voltage should be adopted. with the increase of molten materials, the power load can be increased accordingly until the full load is used. when the charge is basically clear and the arc is exposed, the secondary voltage should be reduced to make the electrode end buried in the slag and maintain the semi arc exposed state, so as to improve the temperature of the molten pool, reduce heat loss and reduce the volatilization loss of manganese. the change of electric load in smelting process is shown in the figure.

3、 smelting operation of shaking furnace production process

this method is a new process for the production of medium and low carbon ferromanganese developed on the basis of foreign "new catharsis method" (hot charging) and "bolun method" (hot blending). several domestic manufacturers have successively carried out industrial tests and achieved remarkable results. on the basis of summarizing the test experience and data of various manufacturers, a low-carbon ferromanganese production line with shaking furnace electric furnace method was designed by beijing iron and steel design and research institute, which was completed and put into operation in zunyi ferroalloy plant in 1990.

1. process principle of shaking furnace pre refining

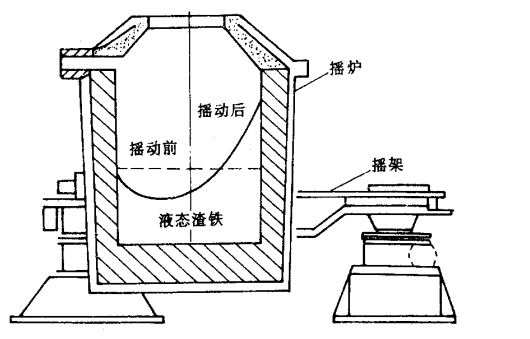

the rocking furnace body sits on a rocking frame. when the rocking frame is rocking, the rocking furnace makes an eccentric circular motion. when it reaches a certain speed, the liquid in the ladle forms sea wave motion driven by the rocking furnace, churning up and down, resulting in strong mixing and stirring, which expands the reaction interface between slag and iron, improves the diffusion speed of reactants and products, and makes the reduction and oxidation reaction between manganese oxide in slag and silicon in alloy fast.

schematic diagram of shaking furnace pre refining

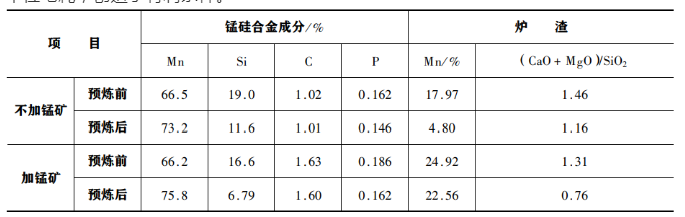

shaking furnace electric furnace method is to put the liquid manganese silicon alloy and liquid medium manganese slag into the shaking furnace, and conduct strong mixing and stirring in the shaking furnace to make the silicon in the manganese silicon alloy react with the manganese oxide in the slag for desilication and manganese reduction, and then put the liquid manganese silicon alloy after removing part of silicon into the refining furnace to smelt with preheated manganese ore and lime to produce medium and low carbon ferromanganese; after shaking furnace treatment, the manganese content of slag is greatly reduced and becomes lean slag. it can be used for manganese silicon alloy smelting, replacing dolomite in whole, replacing silica in part, or used for the production of building materials after water quenching. after shaking furnace pre refining, the manganese content in the alloy increases and the silicon content decreases, which creates favorable conditions for reducing the desilication task in refining furnace smelting, shortening smelting time and reducing unit power consumption of products.

in order to give full play to the advantages of high desilication efficiency of shaking furnace, some dry manganese ore can also be added during pre refining to reduce the silicon in the alloy, which is more favorable for subsequent refining furnace refining.

2. smelting characteristics of shaking furnace electric furnace method

a large number of production practices have proved that compared with the traditional electro silicothermic method, the production of medium and low carbon ferromanganese by shaking furnace electric furnace method has the following advantages: the task of desilication in the refining furnace is reduced. when using electro silicothermic method, the silicon in the manganese silicon alloy needs to be reduced from 18% to less than 2%. after shaking furnace pre refining, the silicon content in the alloy only needs to be reduced from 6-12% to less than 2% in the refining furnace. the amount of manganese ore and slag produced in the refining furnace will be reduced due to the reduction of the amount of manganese ore and slag in the refining furnace. after pre refining in shaking furnace, the manganese content of slag in refining furnace can be appropriately relaxed, and excessive manganese ore can be used for smelting to further speed up the desilication rate. the liquid manganese silicon alloy pretreated in shaking furnace has a large amount of physical sensible heat, which saves the time of electric melting and the corresponding power consumption, and the volatilization loss of manganese in furnace charge is also reduced. the slag discharged from the refining electric furnace is pretreated by shaking furnace. when it is discharged and discarded, the manganese content in the slag is reduced from 12-18% to less than 6%, which greatly improves the recovery rate of manganese.

3. key points of operation

the operation process is as follows: after the iron of the previous furnace is discharged and the hole is blocked, lift the electrode, then rotate the furnace body, and add manganese ore and lime into the furnace at the same time, so that the furnace charge is distributed in a bimodal shape in the furnace. after the furnace charge is added, stop the rotation of the furnace body and let the furnace charge preheat in the furnace. measure the slag discharged from the refining furnace at 1350-1400 ℃ and then put it into the shaking furnace. the liquid manganese silicon alloy at about 1300 ℃ from the reduction furnace is skimmed, sampled and weighed into the shaking furnace and mixed with the slag. start the rotating mechanism of shaking furnace and gradually increase the speed to 55-60 rpm. when the molten liquid wave in the furnace reaches the maximum, add an appropriate amount of dry manganese ore and lime into the furnace through the charging bucket, and flexibly control the shaking time according to the temperature conditions in the furnace. after shaking the furnace for 8 minutes, insert the iron rod into the furnace and take the slag sample for observation. when the slag on the iron rod is in the shape of glass filament and the section is light brown or white, reduce the speed until the shaking stops. dump the shaking furnace, use the transition chute to pour the liquid slag and molten iron into the slag ladle and hot mixing respectively, and the shaken slag is treated as lean slag. the premixed liquid manganese silicon alloy is skimmed, measured and transported to the refining furnace for hot mixing. at the same time, samples are taken to quickly analyze the silicon content, and then the blending material is added accordingly. when the liquid manganese silicon alloy is hot mixed into the refining furnace, the furnace body should rotate to make the alloy melt distribute in a ring along the peak and valley of the furnace charge surface. after the hot blending of the alloy is completed, the furnace body stops rotating and sends electricity for refining. when the charge melts to 70-80%, start the furnace body to rotate, and manually push the charge around the furnace wall to the electrode and the furnace core to promote its rapid melting. after the furnace charge is completely melted, stop rotating the furnace body, sample and judge the silicon, and then cut off the power and discharge the furnace after it is qualified. refer to relevant parts of electro silicothermic method for furnace condition control and out of furnace casting in refining process.

the production of medium and low carbon ferromanganese by shaking furnace electric furnace method has the characteristics of short smelting cycle, high production efficiency, low power consumption and high manganese recovery. once this method came out, it was quickly popularized in domestic ferroalloy plants. now the output of medium and low carbon ferromanganese produced by this method has accounted for about half of the total output of medium and low carbon ferromanganese in china. it has opened a new way for making full use of manganese ore resources and improving smelting economic benefits.

4、 oxygen blowing process and smelting operation

the production of medium and low carbon ferromanganese by oxygen blowing decarbonization method takes the liquid high carbon ferromanganese smelted in reduction electric furnace or blast furnace as the raw material, which is hot mixed into the converter, and oxygen is blown through the oxygen gun to oxidize the carbon in high carbon ferromanganese; at the same time, add an appropriate amount of slagging agent or coolant. when the carbon in the alloy is reduced to meet the standard requirements, the alloy is medium and low carbon ferromanganese. the advantage of producing medium and low carbon ferromanganese by oxygen blowing decarbonization is that blast furnace ferromanganese can be used to broaden the way of producing medium and low carbon ferromanganese. however, due to the high smelting temperature required by this method, the volatilization loss of manganese is large, especially for the production of low-carbon ferromanganese, the smelting temperature needs to be controlled above 1900 ℃, and the volatilization loss of manganese is greater. therefore, how to improve the recovery of manganese is the key to solve the production of this method.

1. key points of operation

fettling. during blowing, the slag corrodes the furnace lining seriously. after coming out of the furnace, it is necessary to make up the furnace with magnesia and brine mixture. make up the furnace quickly at high temperature. alkalinity control. in the early stage of blowing, the alkalinity is controlled at (binary alkalinity) 1.1-1.2. the medium-term alkalinity shall not exceed 2 in the later stage, the alkalinity shall not exceed 6. after adding reducing agent, the alkalinity of slag shall be controlled at 1.1-1.2. under the premise of ensuring rapid decarbonization, in order to reduce the volatilization loss of manganese, the high temperature above 1850 ℃ should be avoided during blowing. when the temperature is too high, an appropriate amount of coolant can be added to cool down. the commonly used coolants are lime, fluorite and medium carbon ferromanganese. end point judgment. accurate end point judgment is an important means to control product quality and improve product qualification rate. it is usually judged according to the flame and oxygen consumption: observe the flue gas flame escaping from the furnace during oxygen blowing. at a certain temperature, the length of the flame depends on the concentration of carbon monoxide and carbon dioxide produced by combustion, and the concentration of carbon monoxide and carbon dioxide indirectly reflects the residual carbon in the alloy; at the later stage of blowing, the residual carbon in the alloy has been relatively low, and the effect of oxygen blowing decarburization has been reduced accordingly. the flame at the furnace mouth appears weak or shrank within the furnace mouth. "oxygen consumption". in practice, it is found that there is a strong corresponding relationship between the consumption of oxygen blowing and the carbon content of molten iron of high-carbon ferromanganese. based on experience, we can judge whether the remaining carbon in the alloy has reached the end of blowing from the consumption of oxygen. if necessary, we can take samples and determine the carbon content by rapid analysis method. add manganese silicon alloy reductant. when the oxygen blowing is over, about 20-30% of manganese in the alloy will be oxidized into the slag, increasing the manganese element in order to improve the recovery rate of manganese, manganese silicon alloy with particle size less than 20mm needs to be added to the furnace to reduce the manganese oxide in the slag. the addition amount of manganese silicon alloy is calculated according to the amount of molten iron into the furnace, the amount of coolant and the type of blowing. generally, the addition amount of manganese silicon alloy is about 20% of the total amount of molten iron and supplementary ferromanganese. it needs to be preheated to 400-500 ℃ before adding into the furnace. tapping and casting. after all the manganese silicon alloy added as reducing agent is melted, it is discharged from the furnace. pour the slag liquid in the furnace together with the molten iron into the molten iron ladle, and use the strong stirring effect during dumping to reduce the manganese oxide in the slag. the alloy liquid is covered with slag in the casting bag or sedation basin, which is left for a period of time to cool down, and then covered with slag for casting, so as to protect the ingot mold from being burned by high-temperature molten iron.

5、 bolen method

one for geoffre ferroalloy plant of french electro metallurgical company "the liquid high silicon manganese silicon alloy with 35% manganese containing silicon produced by the self baking electrode reduction furnace; in addition, the cold pellets are prepared by combining the milled manganese ore with coke powder, roasted in a rotary kiln at 900-1000 ℃, and the burned pellets are poured into the tilting electric furnace for melting. after the pellets are completely melted, all the molten slag is poured into the molten iron ladle containing the liquid high silicon manganese silicon alloy for mixing, and repeatedly inverted with another molten iron ladle for opposite mixing, during which time adding an appropriate amount of lime to slag, the final alloy is low-carbon ferromanganese.

6、 udacon converter process

in 1973, a swedish ferroalloy factory installed an udacon converter with a capacity of 8 tons in its smelting workshop, and 2500kw solution ditch inductor was installed in the lower part of the converter. during production, the liquid manganese silicon alloy produced in the reduction furnace shall be poured into the furnace first, and manganese ore and lime powder shall be sprayed into the alloy liquid with nitrogen as the carrier. when the silicon content in the alloy is reduced to 7%, the slag with low manganese oxide content shall be poured out, and the manganese ore and lime powder shall continue to be sprayed. when the silicon content in the alloy is lower than 1%, the liquid metal shall be poured out, and the slag shall remain in the furnace until the liquid manganese silicon alloy is poured into the next furnace. the liquid metal poured from the converter is cast, condensed and broken into medium and low carbon ferromanganese products. wudakang converter has been running smoothly since it was put into operation. for each ton of medium carbon ferromanganese containing 86% manganese, it consumes 663 kg of manganese silicon alloy containing 20% silicon, 335 kg of lime, 260 degrees of power consumption, 85% manganese recovery and more than 90% silicon utilization.

wechat

wechat